ADDITIONAL SERVICES

Dynamic Metal Innovations offers a variety of additional value-added services to our customers, ideal for producing custom parts of all shapes, sizes and applications. We are also partnered with an array of outside vendors that can help with machining, finishing, heat treating, and other services to produced 100% finished parts.

VALUE-ADDED SERVICES

Below is a list of services we offer, both in-house and from outside vendors. We keep our vendors held to the same level of quality that we require for all of our parts. Our vendors are as committed to quality as we are.

-

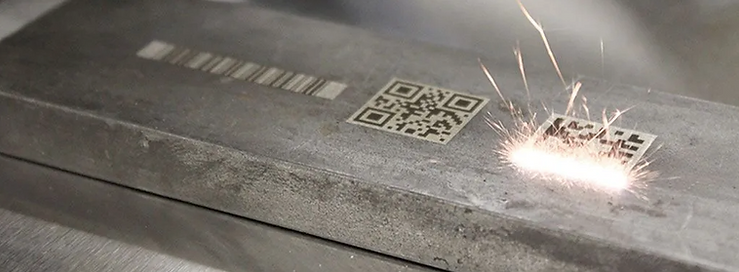

Fiber & CO2 Laser engraving (for part numbers, QR codes, etc)

-

CNC tube laser cutting

-

CNC tube bending

-

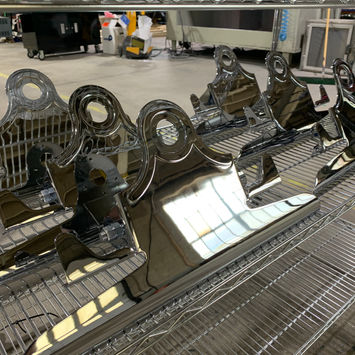

Finishing such as anodizing (Type II and Type III), chem-film, chrome plating, nickel plating, tin plating, etc.

-

Heat treating

-

Black oxide finishing

-

Painting (when powder coating is not an option due to material constraints)

-

Silk screening

-

3D printing

ASSEMBLY

We offer numerous ways to create turn-key assemblies for your project. From simple riveting of components to more complex assembly and wiring, DMI can provide a way to complete an entire project from beginning to end. A dedicated assembly area allows DMI to create an efficient flow to the assembly process. Some of the assembly services we offer include:

-

Component assembly

-

Enclosure assembly

-

Control cabinet wiring

-

Distribution panel wiring

-

Riveting (domed, flush, military style, etc)

-

General bracket/mount assembly

DMI can also assist with designing the necessary fixtures and procedures to make the assembly process as efficient and cost-effective as possible.

PROTOTYPING

DMI can also aid in prototyping new parts from scratch. From reverse-engineering, to creating CAD models from customer drawings, we can help bring ideas and parts to life. We use Autodesk Inventor to model new parts and assemblies. We will work with you to create the initial designs, 3D models, shop drawings, and any other necessary documentation. Then the parts can be produced as prototypes as many times as needed until the parts are ready for their production runs.

QUALITY CONTROL

Making parts that look nice is important, but they also need to perform as designed. DMI takes quality control seriously and takes the necessary measurements at each stage of the manufacturing process to ensure the parts are within spec before going to the next step of the process. If the parts do not meet spec, it is investigated and a solution is determined to either bring the parts within spec or make entirely new parts. The advanced software used to produce the parts typically ensures the parts are always within spec the first time, avoiding wasted time to make corrections.

REQUEST A FREE QUOTE

Fill out the form below and a member of our team will connect with you to discuss your inquiry!